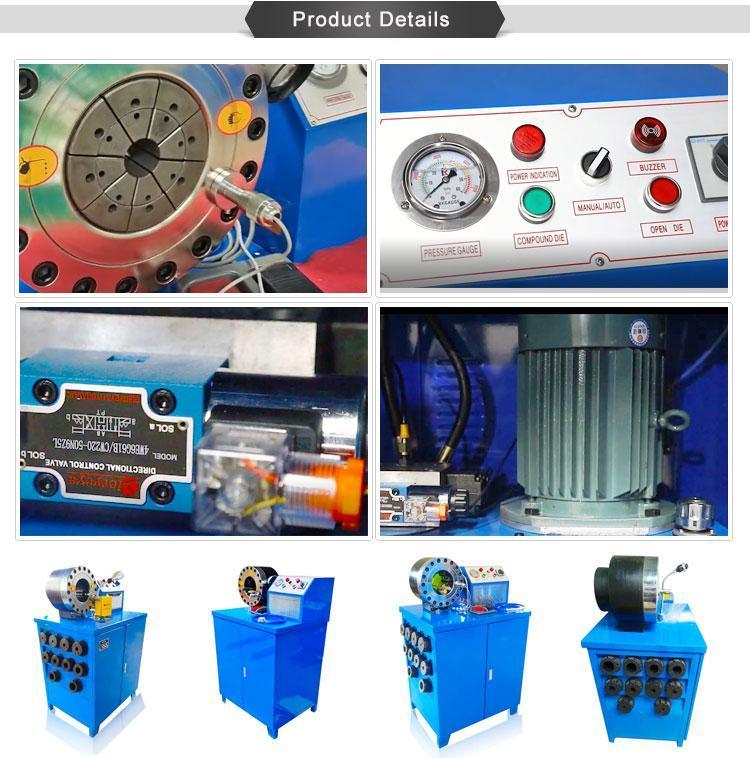

Description

This hose crimping machine is mainly used for buckling processing for high pressure rubber pipe assembly in the mechanical engineering. It can also be used for buckling the two-way bends, especially large bends and irregular shape bends.This machine features small and portable appearance, big force, low noise and easy to operate. The buckling amount can be precise adjusted through a scale. It makes the mould base division to be more even through the double inclined plane eight-flap mould seat equipped with a high accuracy guiding device.

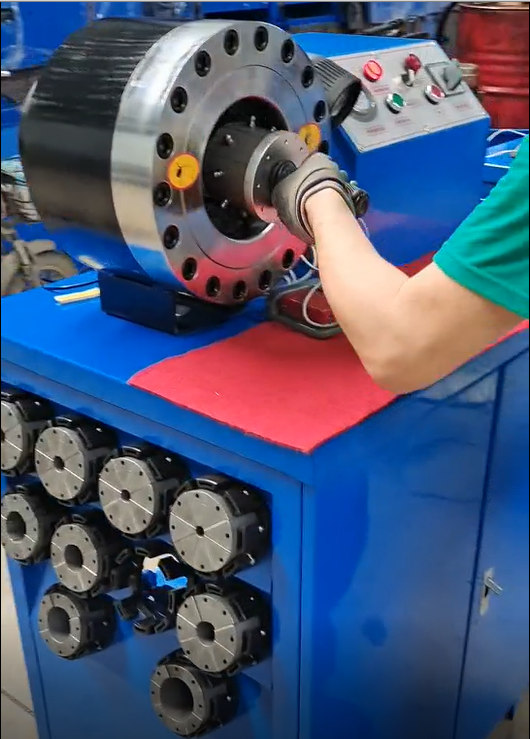

The side of the machine is specially designed to add mold holders to facilitate the access and replacement of the molds, and the machine operation is more convenient and efficient.

The mold opening speed is fast, the weight is light, and the cost is reduced, and is not easy to be damaged, and reduces maintenance costs.

The machine is equipped with a high box, which provides a wider space for the machine, making it easy to place machine parts and other necessary tools.

| Model | DSG250 | DSG250A | DSG250-1 |

| Crimping range(_mm) | 6-51mm | 6-87mm | 6-51mm |

| Qty of dies(set) | 10 | 13 | 10 |

| Crimping precision(mm) | 0.01mm | 0.01mm | 0.01mm |

| Displacement(L) | 5L | 19L | 5L |

| System pressure(Mpa) | 31.5Mpa | 31.5Mpa | 31.5Mpa |

| Power(Kw) | 4Kw | 4Kw | 3Kw |

| Voltage(V) | 220V | 380V | 380V |

| Crimping pressure(T) | 640T | 536T | 500T |

| Efficiency(pc/h) | 200pc/h | 1000pc/h | 200pc/h |

| Dimension(mm) | 700*900*1400 | 800*650*1320 | 800*640*1300 |

| Weight(Kg) | 360KG | 320KG | 300KG |

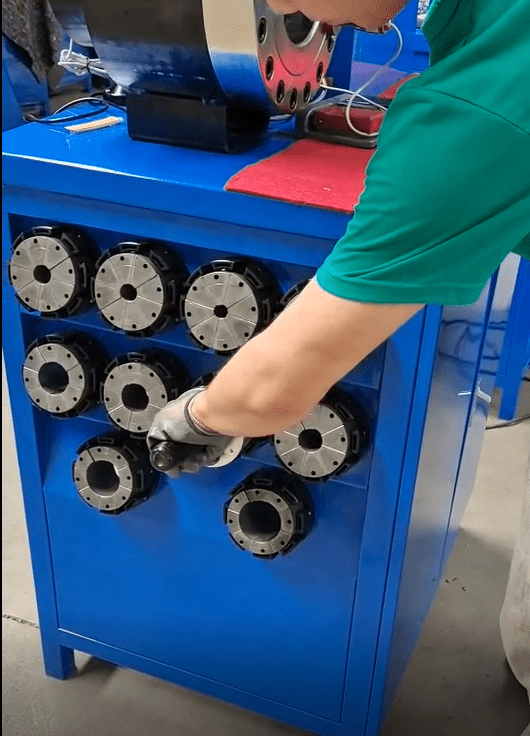

Replace the mold progress

About Hydraulic Hose Pipe Crimping Machine

A hydraulic hose pipe crimping machine is a device used to crimp or press hydraulic hoses and fittings onto hydraulic hoses. These machines are essential for a variety of industries that rely on hydraulic systems, such as construction, manufacturing, and transportation.

The hydraulic hose pipe crimping machine typically consists of a hydraulic pump, a crimping head, and a die set. The hydraulic pump provides the pressure needed to crimp the hose, while the crimping head holds the hose in place and the die set shapes the hose and fitting into the desired shape.

There are many different types and sizes of hydraulic hose pipe crimping machines available, from portable manual machines for small-scale operations to large-scale automated machines for industrial applications. The size and type of machine needed depend on the volume and complexity of the work being done.

Overall, hydraulic hose pipe crimping machines are critical for ensuring that hydraulic hoses are securely and accurately crimped onto fittings, which is crucial for maintaining the safety and efficiency of hydraulic systems.

About Hydraulic Hose Pipe Crimping Machine manufacturer

There are many manufacturers of hydraulic hose pipe crimping machines around the world, each with their own unique features and capabilities. When selecting a manufacturer, it’s important to consider several factors, such as quality, reliability, customer service, and price.

One important factor to consider is the quality of the machines. Look for a manufacturer that uses high-quality materials and components to ensure the durability and longevity of their products. Additionally, consider whether the manufacturer has a reputation for producing reliable machines that perform consistently and accurately over time.

Another important factor to consider is the level of customer service provided by the manufacturer. Look for a manufacturer that offers excellent technical support, training, and after-sales service, to ensure that your investment in their product is well-supported.

Price is also an important consideration when selecting a manufacturer. While it’s important to find a machine that fits your budget, it’s equally important to ensure that you are not sacrificing quality or reliability for a lower price.

Some well-known manufacturers of hydraulic hose pipe crimping machines include Finn-Power, UNIFLEX, Gates Corporation, Parker Hannifin, and Eaton Corporation. However, there are many other reputable manufacturers around the world, so it’s important to do your research and select a manufacturer that meets your specific needs and requirements.

Reviews

There are no reviews yet.