Description

Brief Introduction

Main Technical Feature

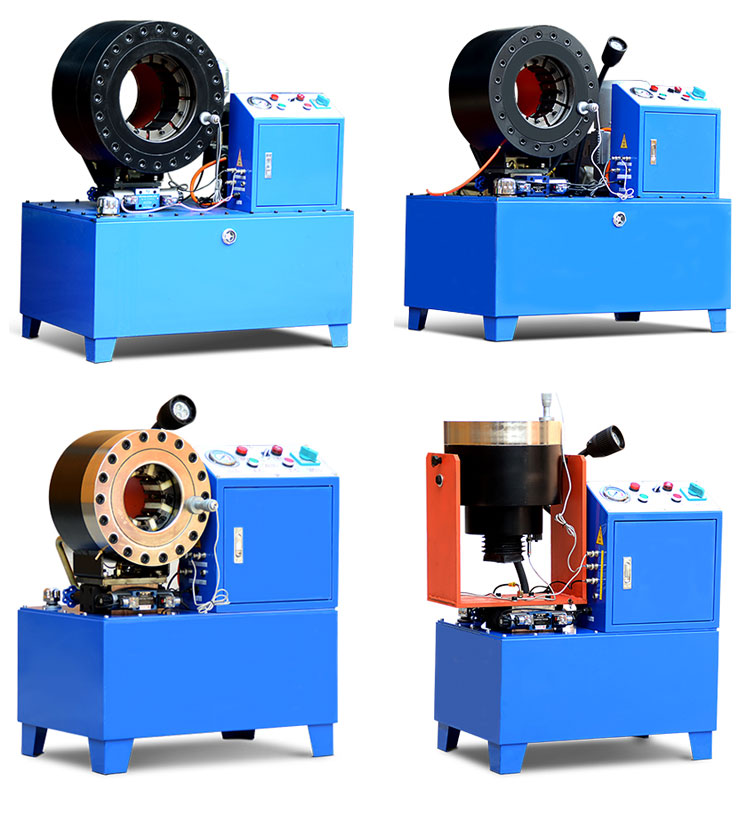

| Hose crimping machine | ||||

| Model | DX68 | DX76 | DX102 | DX150 |

| Crimping range | 6-51mm(1/4″ ~2″) | 6~76mm ( 1/4~3″ ) | 6~102mm ( 1/4~4″ ) | 6-150mm(1/4~6″) |

| Max crimping Force | 449T | 500T | 1400T | 2500T |

| Rated Pressure | 31.5MPa | 50Mpa | 31.5Mpa | 31.5Mpa |

| Weight | 250kg | 300kg | 520kg | 900kg |

| Mold Quantity | 10 sets | 13Sets | 16Sets | 17Sets |

| Power | 3KW/4KW | 4KW | 4KW/5.5KW/7.5KW | 4KW/5.5KW/7.5KW |

| Voltage | 220V/380V | 240V / 380V | 380V or customized | 380V or customized |

| Scale accuracy | 0.02mm | 0.02mm | 0.01mm | 0.01mm |

| Overall dimensions | 670*490*780mm | 730*470*930mm | 900*790*1070mm | 1030*630* 1160mm |

Main Technical Feature

1.Efficient, fast pump

2. dies can be changed quickly by QC tool

3. Die set rack,space saving.

4. Precision control device,equipped with signal lamp

5. automatic&semi-auto&button& foot pedal control operated

6.The height of the machine is just right for standing operation

Notices

Maintenance

About fuel line crimping tool

A fuel line crimping tool is a specialized tool used for crimping and securing fuel lines to fittings or connectors. These tools are typically used in automotive or other mechanical applications where a secure and leak-proof connection is critical for the safe operation of the vehicle or machinery.

The fuel line crimping tool is designed to crimp the metal or plastic fitting onto the fuel line, creating a secure and tight seal that prevents fuel leaks. These tools come in various sizes and types to accommodate different types and sizes of fuel lines, and they are typically designed to be easy to use and provide a consistent and uniform crimp.

When using a fuel line crimping tool, it is important to follow the manufacturer’s instructions carefully to ensure a proper crimp and a secure connection. It is also important to use the correct size and type of tool for the fuel line and fitting being used to prevent damage or leaks.

Overall, a fuel line crimping tool is an essential tool for any mechanic or technician working on fuel lines in automotive or other mechanical applications, as it ensures a safe and secure connection that is vital for the proper operation of the vehicle or machinery.

Fuel line crimping tool manufacturer

Fuel line crimping tool manufacturers produce tools that are specifically designed to crimp and secure fuel lines to fittings or connectors. Some of the most important considerations when selecting a fuel line crimping tool manufacturer include the quality of the tools they produce, the range of sizes and types of tools available, and the level of customer support and service they provide.

Quality is an essential factor when choosing a fuel line crimping tool manufacturer, as these tools are critical for ensuring the safe and reliable operation of vehicles and machinery. Manufacturers that produce high-quality tools using durable materials and precision manufacturing processes can provide greater reliability and performance over time.

The range of sizes and types of tools available is another important factor to consider. Different manufacturers may offer different tool designs, sizes, and capabilities, so it’s important to select a manufacturer that offers tools that meet your specific needs and requirements.

Customer support and service is also an essential consideration when choosing a fuel line crimping tool manufacturer. Manufacturers that provide comprehensive customer support, such as technical assistance, troubleshooting, and repair services, can help ensure that you get the most out of your fuel line crimping tools and that they perform reliably over time.

Some of the top fuel line crimping tool manufacturers include Koul Tools, OTC, Eastwood, JEGS, and Vise Grip, among others. When selecting a manufacturer, it’s important to carefully research their products and reputation to ensure that you choose a manufacturer that can provide the quality, range of tools, and customer support that you need for your specific application.

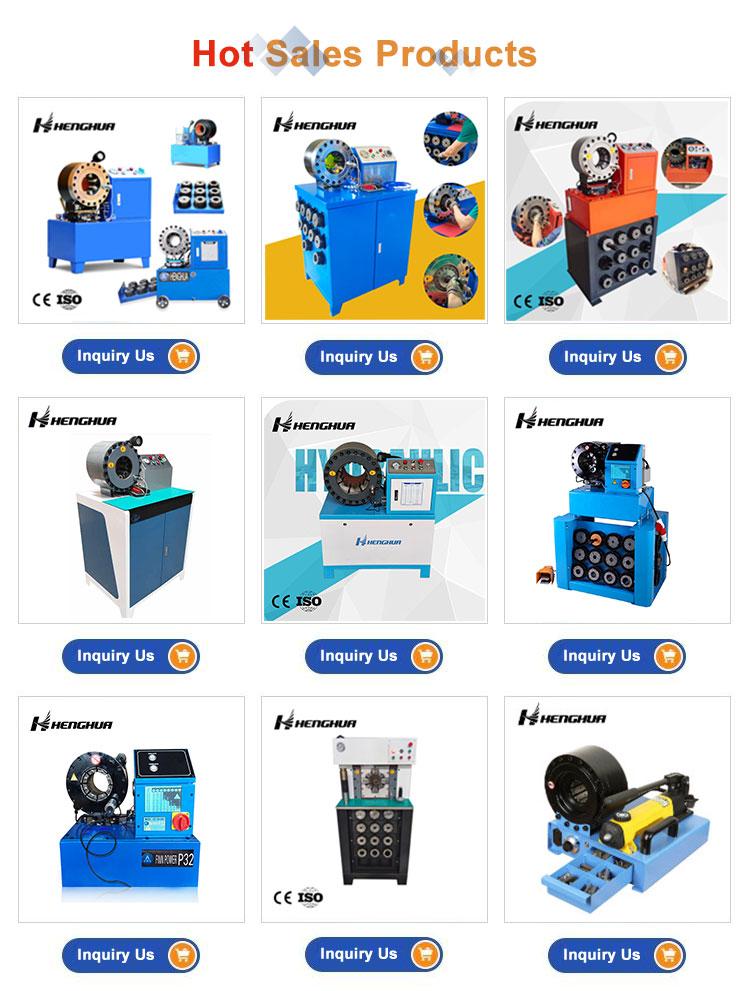

There are many other hydraulic hose pipe crimping machine manufacturers out there as well. It’s important to do your research and choose a manufacturer that offers a high-quality product with good customer service and support.

Reviews

There are no reviews yet.