Description

Brief Introduction

Main Technical Feature

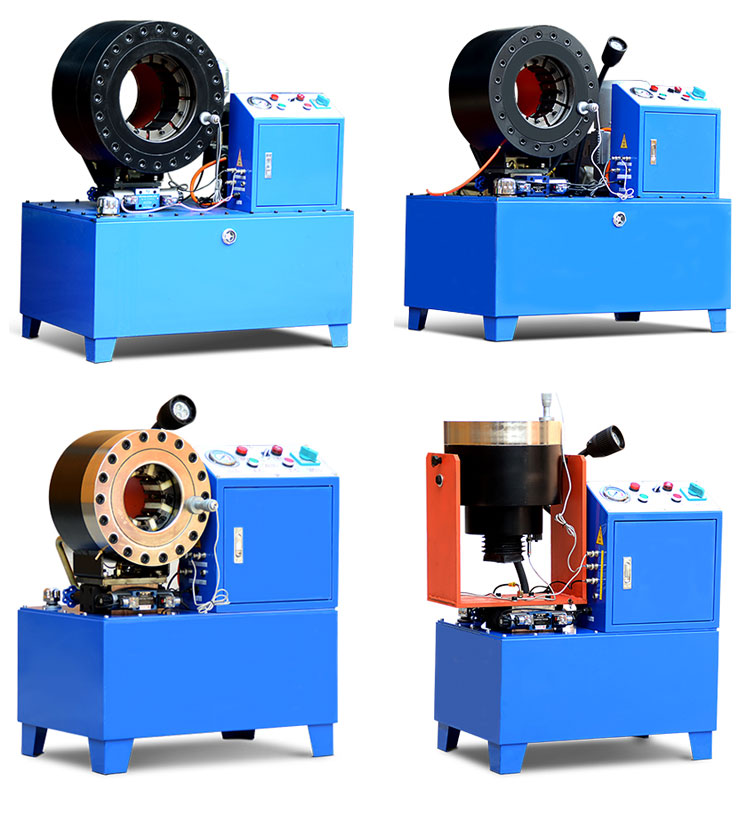

| Hose crimping machine | ||||

| Model | DX68 | DX76 | DX102 | DX150 |

| Crimping range | 6-51mm(1/4″ ~2″) | 6~76mm ( 1/4~3″ ) | 6~102mm ( 1/4~4″ ) | 6-150mm(1/4~6″) |

| Max crimping Force | 449T | 500T | 1400T | 2500T |

| Rated Pressure | 31.5MPa | 50Mpa | 31.5Mpa | 31.5Mpa |

| Weight | 250kg | 300kg | 520kg | 900kg |

| Mold Quantity | 10 sets | 13Sets | 16Sets | 17Sets |

| Power | 3KW/4KW | 4KW | 4KW/5.5KW/7.5KW | 4KW/5.5KW/7.5KW |

| Voltage | 220V/380V | 240V / 380V | 380V or customized | 380V or customized |

| Scale accuracy | 0.02mm | 0.02mm | 0.01mm | 0.01mm |

| Overall dimensions | 670*490*780mm | 730*470*930mm | 900*790*1070mm | 1030*630* 1160mm |

Main Technical Feature

1.Efficient, fast pump

2. dies can be changed quickly by QC tool

3. Die set rack,space saving.

4. Precision control device,equipped with signal lamp

5. automatic&semi-auto&button& foot pedal control operated

6.The height of the machine is just right for standing operation

Notices

Maintenance

About hydraulic hose pipe crimping machine

A hydraulic hose pipe crimping machine is a device that is used to crimp or connect two ends of a hydraulic hose together. The machine uses a hydraulic system to apply pressure to a die, which compresses the hose and fittings together, creating a secure and leak-free connection.

There are different types of hydraulic hose pipe crimping machines available, including manual, semi-automatic, and fully automatic machines. Manual machines require the operator to manually operate the pump to apply pressure to the die, while semi-automatic and fully automatic machines have an electric or hydraulic pump that applies pressure automatically.

The crimping process typically involves several steps, including cutting the hose to the appropriate length, selecting the correct fittings and hose diameter, and setting up the crimping machine to apply the proper amount of pressure.

Proper training and safety precautions are important when using a hydraulic hose pipe crimping machine, as the high pressures involved can pose a risk of injury if not handled correctly. Regular maintenance and inspection of the machine and its components are also important to ensure safe and reliable operation.

About hydraulic hose pipe crimping machine manufacturer

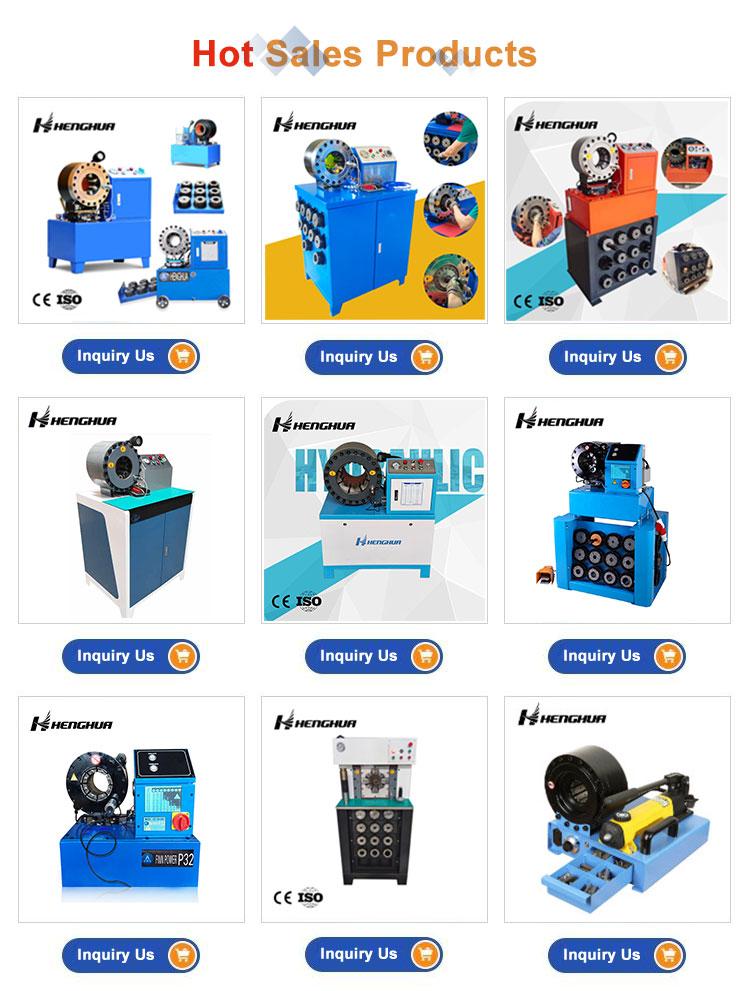

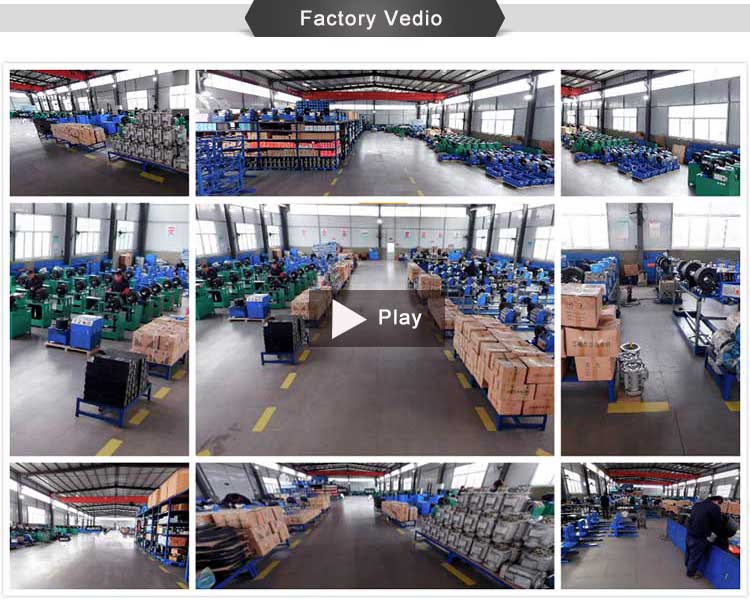

Hydraulic hose pipe crimping machine manufacturers design, develop and produce hydraulic hose crimping machines for a wide range of industrial and commercial applications. These manufacturers typically offer a variety of models with different specifications to suit different customer needs.

When choosing a hydraulic hose pipe crimping machine manufacturer, it is important to consider factors such as the quality of their products, their experience and reputation in the industry, their after-sales service and support, and their ability to meet your specific requirements.

Some of the key features to look for in a reputable hydraulic hose pipe crimping machine manufacturer include:

- Quality: Look for a manufacturer that uses high-quality materials and components to ensure reliable and durable products.

- Customization: Choose a manufacturer that can customize their machines to meet your specific requirements and needs.

- Support: Look for a manufacturer that provides technical support, training, and after-sales service to ensure smooth operation and maintenance of their products.

- Certification: Choose a manufacturer that meets relevant international standards and certifications, such as CE, ISO, and UL.

- Reputation: Check the manufacturer’s reputation in the market by looking for reviews and feedback from their previous customers.

Some of the top hydraulic hose pipe crimping machine manufacturers in the market include Uniflex, Finn-Power, Parker Hannifin, Gates Corporation, and OP Srl.

Reviews

There are no reviews yet.