Description

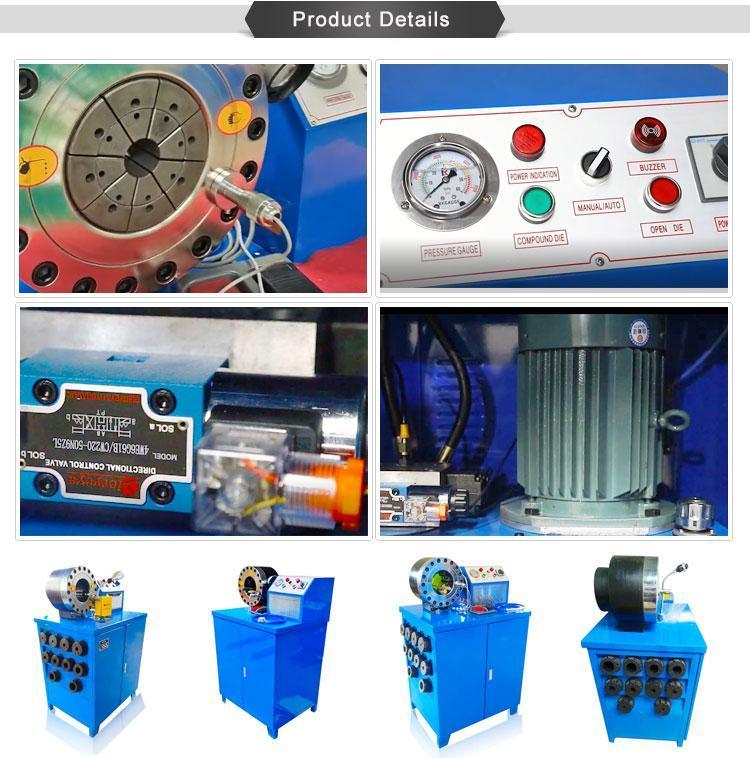

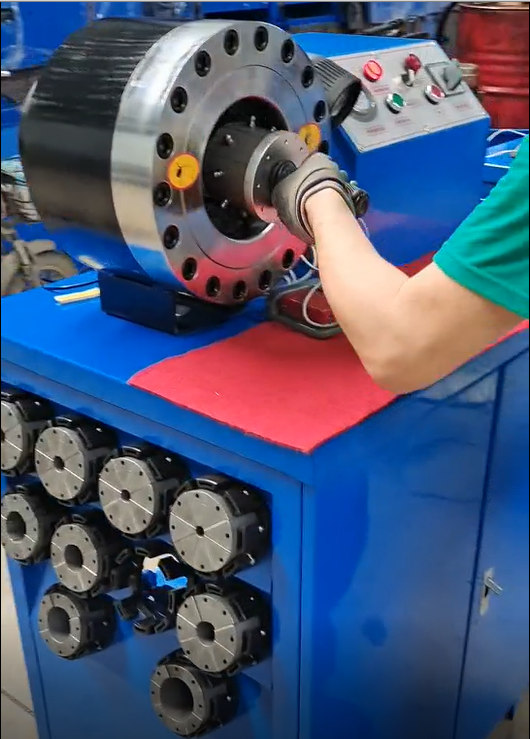

This hose crimping machine is mainly used for buckling processing for high pressure rubber pipe assembly in the mechanical engineering. It can also be used for buckling the two-way bends, especially large bends and irregular shape bends.This machine features small and portable appearance, big force, low noise and easy to operate. The buckling amount can be precise adjusted through a scale. It makes the mould base division to be more even through the double inclined plane eight-flap mould seat equipped with a high accuracy guiding device.

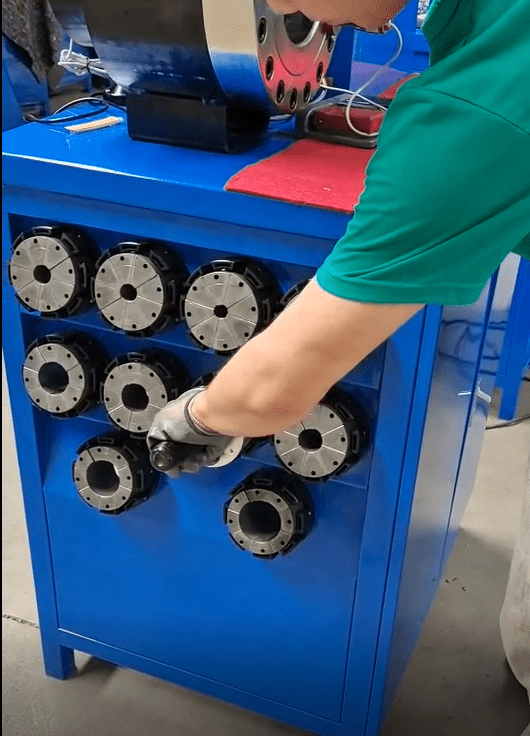

The side of the machine is specially designed to add mold holders to facilitate the access and replacement of the molds, and the machine operation is more convenient and efficient.

The mold opening speed is fast, the weight is light, and the cost is reduced, and is not easy to be damaged, and reduces maintenance costs.

The machine is equipped with a high box, which provides a wider space for the machine, making it easy to place machine parts and other necessary tools.

| Model | DSG250 | DSG250A | DSG250-1 |

| Crimping range(_mm) | 6-51mm | 6-87mm | 6-51mm |

| Qty of dies(set) | 10 | 13 | 10 |

| Crimping precision(mm) | 0.01mm | 0.01mm | 0.01mm |

| Displacement(L) | 5L | 19L | 5L |

| System pressure(Mpa) | 31.5Mpa | 31.5Mpa | 31.5Mpa |

| Power(Kw) | 4Kw | 4Kw | 3Kw |

| Voltage(V) | 220V | 380V | 380V |

| Crimping pressure(T) | 640T | 536T | 500T |

| Efficiency(pc/h) | 200pc/h | 1000pc/h | 200pc/h |

| Dimension(mm) | 700*900*1400 | 800*650*1320 | 800*640*1300 |

| Weight(Kg) | 360KG | 320KG | 300KG |

Replace the mold progress

About Hydraulic Hose Crimping Machine

A hydraulic hose crimping machine is a device used to crimp, or attach, end fittings to hydraulic hoses. These machines use a hydraulic ram to apply pressure and compress the fitting onto the hose.

The crimping process is important because it ensures that the fitting is securely attached to the hose and can withstand the high pressures and vibrations that hydraulic systems operate under. A properly crimped fitting also provides a leak-free connection, which is crucial for the safe and efficient operation of hydraulic systems.

Hydraulic hose crimping machines are available in a range of sizes and configurations, from portable units for field use to large, industrial machines for high-volume production. Some machines are manual, while others are automated and can perform multiple crimps with minimal operator intervention.

When selecting a hydraulic hose crimping machine, it is important to consider the types of hoses and fittings that will be used, as well as the volume of crimps that will be performed. It is also important to ensure that the machine is compatible with the hydraulic system being used, as different systems may have different pressure and fitting requirements.

About Hydraulic Hose Crimping Machine manufacturer

Hydraulic hose crimping machines are manufactured by a variety of companies around the world. These manufacturers specialize in producing machines that are designed to crimp hoses of various sizes and types, as well as to meet the specific needs of different industries.

When choosing a hydraulic hose crimping machine manufacturer, there are several factors to consider. First, it is important to ensure that the manufacturer has a good reputation for producing high-quality machines that are reliable and durable. This can be done by checking online reviews, as well as by speaking with other industry professionals who have experience with the manufacturer’s products.

Second, it is important to choose a manufacturer that offers a wide range of machines to choose from, as well as a variety of different options for customization. This can help ensure that the machine is tailored to meet the specific needs of the industry and the particular application.

Third, it is important to consider the manufacturer’s customer service and support capabilities. This includes things like technical support, training, and after-sales service. A good manufacturer will offer comprehensive support to help ensure that the machine is properly installed, operated, and maintained over its lifespan.

Finally, it is important to consider the price of the machine, as well as any additional costs associated with installation, maintenance, and repairs. While it may be tempting to choose the cheapest option, it is important to ensure that the machine is of good quality and that it will provide reliable performance over the long term.

Reviews

There are no reviews yet.