Description

Brief Introduction

Main Technical Feature

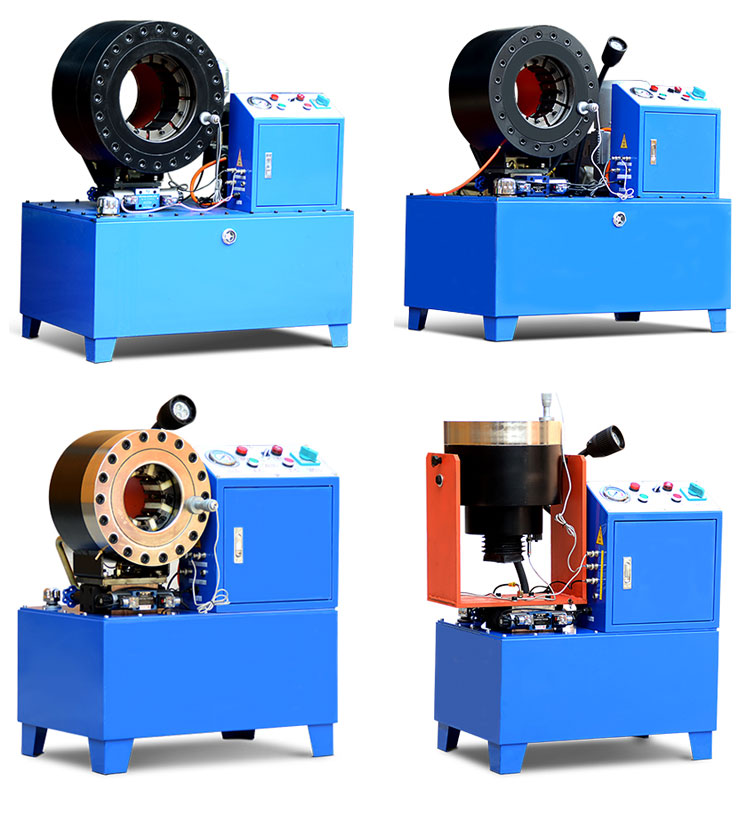

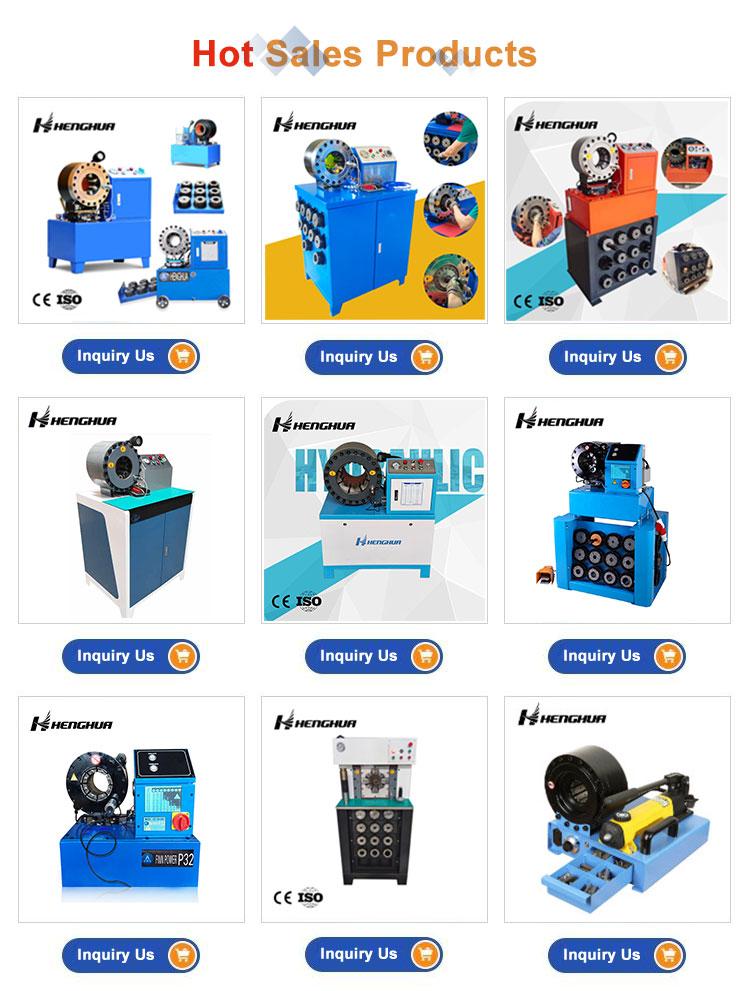

| Hose crimping machine | ||||

| Model | DX68 | DX76 | DX102 | DX150 |

| Crimping range | 6-51mm(1/4″ ~2″) | 6~76mm ( 1/4~3″ ) | 6~102mm ( 1/4~4″ ) | 6-150mm(1/4~6″) |

| Max crimping Force | 449T | 500T | 1400T | 2500T |

| Rated Pressure | 31.5MPa | 50Mpa | 31.5Mpa | 31.5Mpa |

| Weight | 250kg | 300kg | 520kg | 900kg |

| Mold Quantity | 10 sets | 13Sets | 16Sets | 17Sets |

| Power | 3KW/4KW | 4KW | 4KW/5.5KW/7.5KW | 4KW/5.5KW/7.5KW |

| Voltage | 220V/380V | 240V / 380V | 380V or customized | 380V or customized |

| Scale accuracy | 0.02mm | 0.02mm | 0.01mm | 0.01mm |

| Overall dimensions | 670*490*780mm | 730*470*930mm | 900*790*1070mm | 1030*630* 1160mm |

Main Technical Feature

1.Efficient, fast pump

2. dies can be changed quickly by QC tool

3. Die set rack,space saving.

4. Precision control device,equipped with signal lamp

5. automatic&semi-auto&button& foot pedal control operated

6.The height of the machine is just right for standing operation

Notices

Maintenance

About Hydraulic Hose Crimp Fittings

Hydraulic hose crimp fittings are devices used to connect hydraulic hoses to other hydraulic components, such as pumps, valves, cylinders, and motors. They consist of a metal sleeve, or ferrule, that is placed over the end of the hose and crimped onto it using a hydraulic hose crimping machine. The crimped ferrule forms a tight seal between the hose and the component, allowing hydraulic fluid to flow between them without leakage.

There are different types of hydraulic hose crimp fittings available, such as one-piece and two-piece fittings. One-piece fittings are typically used in low-pressure applications, while two-piece fittings are used in higher-pressure applications. Two-piece fittings also offer more flexibility, as the hose and the component can be disconnected without having to replace the entire fitting.

Hydraulic hose crimp fittings are commonly made of materials such as steel, brass, and stainless steel. The material used will depend on the application, as different materials have different properties, such as strength, corrosion resistance, and temperature tolerance.

Proper installation of hydraulic hose crimp fittings is important to ensure safe and effective operation of the hydraulic system. The hose and the fitting must be compatible and the crimping process must be done correctly to ensure a secure and leak-free connection. Regular maintenance and inspection of the hydraulic system, including the fittings, is also important to identify any potential issues and prevent failures.

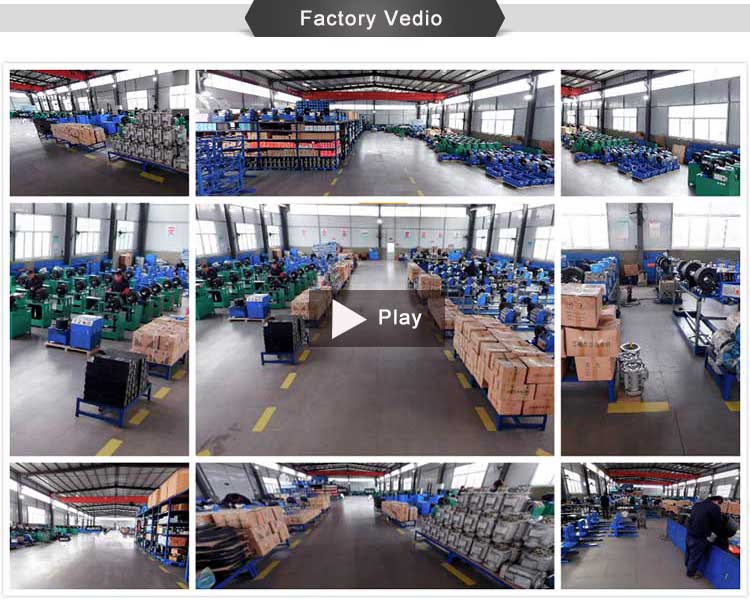

About Hydraulic Hose Crimp Fittings Manufacturer

Hydraulic hose crimp fittings are manufactured by a variety of companies around the world, ranging from small specialized manufacturers to large multinational corporations. When choosing a hydraulic hose crimp fittings manufacturer, it is important to consider factors such as quality, reliability, pricing, lead time, and customer support.

Here are some key factors to consider when evaluating a hydraulic hose crimp fittings manufacturer:

- Quality: The quality of the hydraulic hose crimp fittings is critical for ensuring safe and reliable operation of hydraulic systems. Look for manufacturers that have a strong reputation for producing high-quality products that meet industry standards and regulations.

- Reliability: A manufacturer that consistently delivers reliable and consistent quality products can help minimize downtime and improve operational efficiency.

- Pricing: Compare pricing from different manufacturers to ensure that you are getting the best value for your money. It’s important to note that the lowest price may not always be the best option, as it may come at the expense of quality and reliability.

- Lead time: Consider the lead time for the manufacturer to produce and deliver the hydraulic hose crimp fittings. A quick turnaround time can help you get your hydraulic system up and running faster.

- Customer support: A manufacturer that provides strong customer support can help you address any issues or concerns that may arise with your hydraulic hose crimp fittings. Look for manufacturers that offer technical support and training, as well as a responsive customer service team.

Some of the well-known manufacturers of hydraulic hose crimp fittings include Parker Hannifin, Gates Corporation, Eaton Corporation, and Kurt Manufacturing Company. However, there are many other manufacturers that produce high-quality hydraulic hose crimp fittings, so it’s important to do your research and choose a manufacturer that meets your specific needs and requirements.

Reviews

There are no reviews yet.